Logistics and shipping

Process-optimisation systems

Success-Stories

Globalisation forces vehicle manufacturers to continuously shorten their production times, reduce manufacturing costs and optimise their processes. This means that the suppliers also have to rethink their logistics processes. The global technology company Continental employs the “just-in-sequence” principle in Regensburg to ensure that the necessary materials are delivered to the production line in perfect sequence.

Lean structures and lean processes are a challenge for every company. In order to optimise the efficiency of the value adding processes and to improve the company’s competitive standing, Höft & Wessel use a simple machine data recording system from WERMA Signaltechnik.

StockSAVER is a maintenance-free system which is easy to retrofit to any FIFO flow rack.Sensors fitted to the flow racks ensure complete transparency of stock levels and safeguard against material running out or misplaced stock.The system works very simply:sensors monitor the number if bins held on the FIFO flow racks.

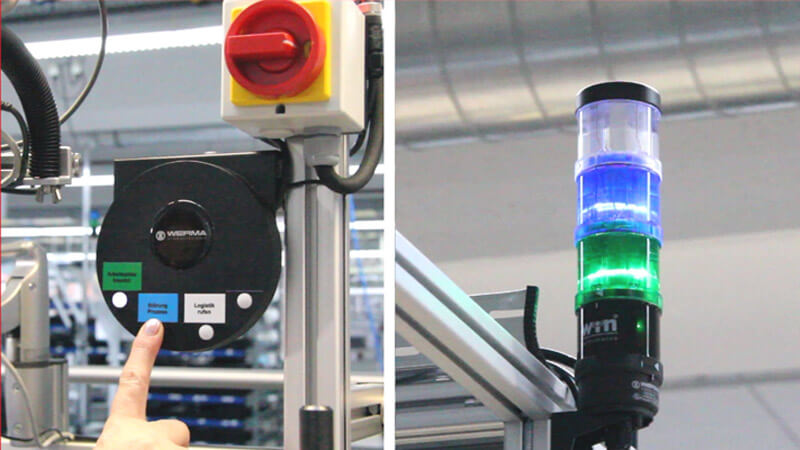

Each check-out is fitted with an Andon SmartBOX which the member of staff activities by pressing the appropriate button to indicate that the check-out is open or closed or that there is a particular problem that needs to be resolved. The status is indicated by the clearly visible appropriate signal light color.

StockSAVER offers a robust error-free system as it is no longer necessary to scan withdraw-als of stock neither is there a danger of duplicate bookings being made nor are arithmetically calculated stock level errors possible.