Hygienic design

For the pharmaceutical and food industries

Guidelines and regulations

WERMA’s system of hygienic design is based on the following guidelines, amongst others:

- Machinery directive 2006/42/EC (Annex I, Section 2.1): Machinery intended for use with foodstuffs or with cosmetics or pharmaceutical products

- DIN EN 1672-2-2005: Food processing machinery - Basic concepts, Part 2: Hygiene requirements

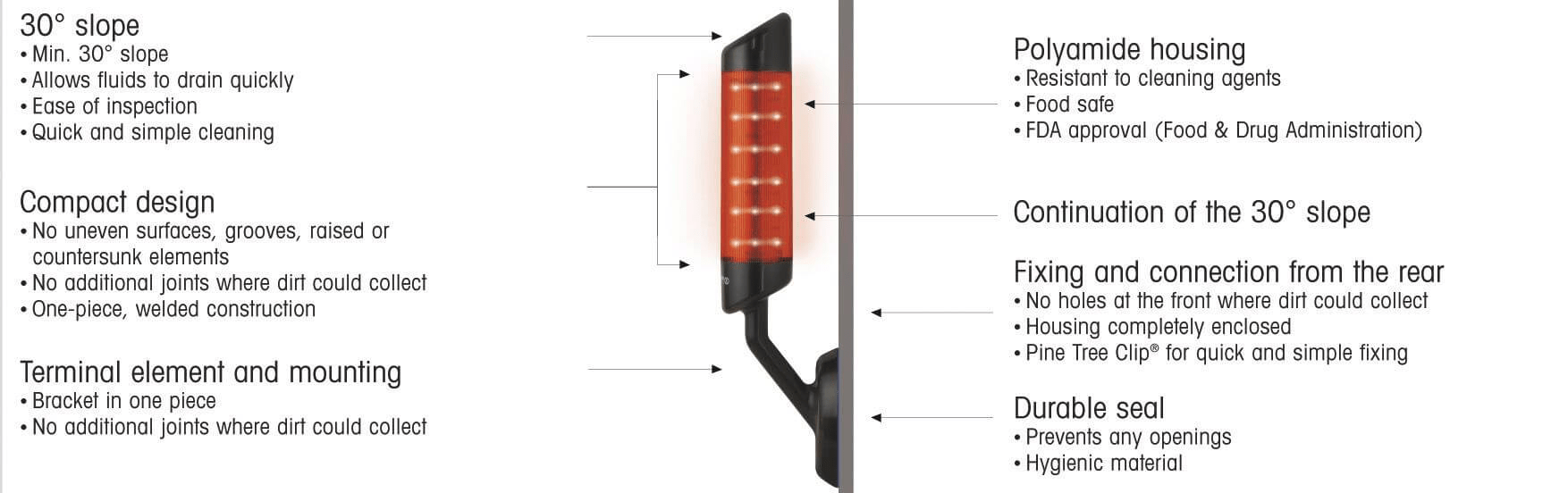

The solution: CleanSIGN LED signal tower

CleanSIGN was specially developed and constructed by WERMA for use in areas with strict hygiene requirements. The relevant standards and guidelines were taken into account right from the start, as were the requirements of experts and specialists in the field of hygienic design. CleanSIGN is the world’s first signalling device to be developed in line with European Machinery Directive 2006/42/EC and hygiene standards. Thanks to its revolutionary shape, smooth surfaces and selected materials, CleanSIGN meets the high standards of hygienic design. CleanSIGN has no grooves or seams that could collect dirt, for example. So it is easy and quick to clean. This is a prerequisite and an important contribution to the safe and clean production of foodstuffs, cosmetics and pharmaceutical products.