EU Machinery Directive 2006/42/EC

Safety-related signal technology

The European Machinery Directive 2006/42/EC

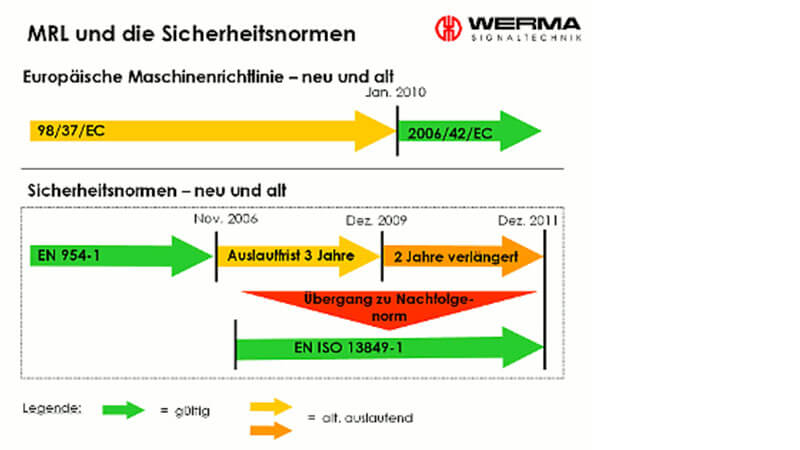

The new Machinery Directive 2006/42/EC requires machinery manufacturers to carry out a more stringent safety analysis for machinery and plant.

The directive refers to standards that regulate the risk analysis. After a transition phase from the old to the new safety standards, this is obligatory for all machinery manufacturers from the end of 2011 onwards. This means that, from the earliest design stage onwards, engineers must factor in characteristic values for safety-related machine parts.

The new safety standard EN ISO 13849-1

European standard EN ISO 13849-1 ”Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design” concerns all types of control systems and machinery. It regulates part of the risk analysis for machines in accordance with the machinery directive.

In accordance with the standard, all components – meaning all parts and devices that affect the safety of the machine – are evaluated by and allocated characteristic values in order to determine the expected safety of the machine. One of these safety characteristic values is the MTTFd value. The “Performance Level” (PL) is determined at the end of the analysis.

Safety standard EN ISO 13849-1 applies here:

- European Union

- Iceland

- Norway

- Switzerland

Since the end of 2011, the more stringent safety analysis is obligatory for everyone. The transition period of the old safety standards expired on that date.

Normal indicating or warning devices – all WERMA signalling devices are suitable!

The following applies in general: All WERMA signalling devices are suitable for machine signalling in compliance with the new European Machinery Directive 2006/42/EC (since 29.12.2009). However, a distinction must be made between safety-related and non-safety-related applications, since: Many informative signal applications are not relevant to safety. For example: a signalling device may be used simply to inform someone whether a process is finished or still running. Such devices are often used to identify downtimes and improve economic efficiency.

Safety-related signalling devices and risk analysis

When are signalling devices safety-related? – Risk analysis

The illustration shows in which cases signalling devices with safety values must be used.

Within the framework of a risk analysis, the design engineer must use an iterative process to determine whether the machine being developed is associated with safety risks. If there are risks, then the engineer must build in precautionary features to prevent these risks.

Signalling devices may form part of such a precautionary feature. An acoustic buzzer can warn a machine operator in good time before a failing vacuum causes a weight to drop, for instance. In this case, the signalling device is safety-related. These safety-related signalling devices, with their characteristic values, must be included in the risk analysis of the machine. The German test institute TÜV has determined and confirmed the MTTFd and PL values of selected WERMA signalling devices.

SISTEMA – an important tool for calculating risks

SISTEMA is an aid used for calculating the machine risk. It is free software provided by the German Institute for Occupational Safety and Health. SISTEMA can be downloaded from the Institute’s website without registration.

With the help of this software, anyone can evaluate and determine the safety of machines. Amongst other things, the program assists in calculating the “Performance Level” (PL).

Simply download: SISTEMA database with more than 100 WERMA signalling devices

WERMA has prepared a database for SISTEMA, which incorporates the WERMA signalling devices with safety values tested by the TÜV test institute. Design engineers can quickly and easily download the database containing the signalling devices and their safety values, without having to register on the website.

Tested safety: WERMA signalling devices

Safety values save time for design engineers

WERMA commissioned the TÜV test institute to determine the safety values for selected signalling devices. These values can be incorporated immediately into the machine manufacturer’s risk analysis. It simplifies the manufacturer’s design process and saves him time.

Signalling devices with the best MTTFd value – confirmed by TÜV

The MTTFd value describes the statistical mean operating time to dangerous failure (in accordance with EN ISO 13849-1). These signalling devices all achieve the highest safety value MTTFd > 100 years.